SITRANS P DS III series for gauge and absolute pressure, with flush-mounted diaphragm | ||||

|---|---|---|---|---|

HART | PROFIBUS PA and FOUNDATION Fieldbus | |||

Input of gauge pressure, with flush-mounted diaphragm | ||||

Measured variable | Gauge pressure, flush-mounted | |||

Spans (infinitely adjustable) or nominal measuring range and max. permissible test pressure | Span (min. ... max.) | Max. perm. test pressure | Nominal measuring range | Max. perm. test pressure |

0.01 ... 1 bar g | 6 bar g | 1 bar g | 6 bar g | |

0.04 ... 4 bar g | 10 bar g | 4 bar g | 10 bar g | |

0.16 ... 16 bar g | 32 bar g | 16 bar g | 32 bar g | |

0.6 ... 63 bar g | 100 bar g | 63 bar g | 100 bar g | |

Lower measuring limit | 100 mbar a (1.45 psi a) | |||

Upper measuring limit | 100% of max. span | 100% of the max. nominal measuring range | ||

Input of absolute pressure, with flush-mounted diaphragm | ||||

Measured variable | Absolute pressure, flush-mounted | |||

Spans (infinitely adjustable) or | Span (min. ... max.) | Max. perm. test pressure | Nominal measuring range | Max. perm. test pressure |

43 ... 1300 mbar a | 10 bar a | 1300 mbar a | 10 bar a | |

0,16 ... 5 bar a | 30 bar a | 5 bar a | 30 bar a | |

1 ... 30 bar a | 100 bar a | 30 bar a | 100 bar a | |

Lower measuring limit | 0 bar a (0 psi a) | |||

Upper measuring limit | 100% of max. span | 100% of the max. nominal measuring range | ||

Output | ||||

Output signal | 4 ... 20 mA | Digital PROFIBUS PA and FOUNDATION Fieldbus signal | ||

| 3.55 mA, factory preset to 3.84 mA | - | ||

| 23 mA, factory preset to 20.5 mA or optionally set to 22.0 mA | - | ||

Load | ||||

| RB ≤ (UH - 10.5 V)/0.023 A in Ω, | - | ||

| RB = 230 ... 500 Ω (SIMATIC PDM) or | - | ||

Physical bus | - | IEC 61158-2 | ||

Protection against polarity reversal | Protected against short-circuit and polarity reversal. Each connection against the other with max. supply voltage. | |||

Measuring accuracy | Acc. to IEC 60770-1 | |||

Reference conditions | Increasing characteristic, start-of-scale value 0 bar, stainless steel seal diaphragm, silicone oil filling, room temperature 25 °C (77 °F), r: Span ratio | |||

Error in measurement at limit setting incl. hysteresis and reproducibility | ||||

Gauge pressure, | Absolute pressure, | Gauge pressure, | Absolute pressure, | |

| ≤ 0,075 % | ≤ 0,2 % | ||

| ≤ (0.0029 · r + 0.071) % | ≤ 0,2 % | ||

| ≤ (0.0045 · r + 0.071) % | ≤ 0,4 % | ||

| ≤ (0.005 · r + 0.05) % | |||

Long-term stability (temperature change ± 30 °C (± 54 °F)) | ≤ (0.25 · r) % per 5 years | ≤ 0.25 % per 5 years | ||

Influence of ambient temperature | ||||

| ≤ (0.1 · r + 0.2) %1) | ≤ (0.2 · r + 0.3) % | ≤ 0,3 % | ≤ 0,5 % |

| ≤ (0.1 · r + 0.15) %/10 K | ≤ (0.2 · r + 0.3) %/10 K | ≤ 0.25 %/10 K | ≤ 0.5 %/10 K |

Influence of mounting position | 0.1 mbar g (0.00145 psi g) per 10° inclination | |||

Measured Value Resolution | - | 3 · 10-5 of nominal measuring range | ||

Influence of the medium temperature (only with flush-mounted diaphragm) | ||||

| 3 mbar/10 K (0.04 psi/10 K) | |||

Rated conditions | ||||

Installation conditions | ||||

Ambient temperature | Observe the temperature class in areas subject to explosion hazard. | |||

| -40 ... +85 °C (-40 ... +185 °F) | |||

| -10 ... +85 °C (14 ... +185 °F) | |||

| -20 ... +85 °C (-4 ... +185 °F) | |||

| -30 ... +85 °C (-22 ... +185 °F) | |||

| -50 ... +85 °C (-58 ... +185 °F) | |||

| ||||

| Relative humidity 0 ... 100 % | |||

Degree of protection (to IEC 60529) | IP65, IP68, NEMA 4X, enclosure cleaning, resistant to lyes, steam to 150 ° C (302 °F) | |||

| ||||

| Acc. to EN 61326 and NAMUR NE 21 | |||

Medium conditions | ||||

Temperature of medium | The max. medium temperature of the front-flush process connections is to be taken into account in accordance with the relevant connection standards (e. g. DIN 32676, DIN 11851 etc.). | |||

| -40 ... +100 °C (-40 ... +212 °F) | |||

| -40 ... +150 °C (-40 ... +302 °F) | |||

| -10 ... +150 °C (14 ... 302 °F) | |||

| -40 ... +200 °C (-40 ... +392 °F) | |||

| -20 ... +100 °C (-4 ... +212 °F) | |||

| -10 ... +250 °C (14 ... 482 °F) | |||

Design | ||||

Weight (without options) | ≈ 1.5 kg (≈ 3.3 lb) | |||

Enclosure material | Low-copper die-cast aluminum, GD-AlSi 12 or stainless steel precision casting, mat. no. 1.4408 | |||

Wetted parts materials | Stainless steel, mat. no. 1.4404/316L | |||

Measuring cell filling | Silicone oil or inert filling liquid | |||

Process connection |

| |||

Surface quality touched-by-media | Ra-values ≤ 0.8 µm (32 µ-inch)/welds Ra) ≤ 1.6 µm (64 µ-inch) (Process connectionsaccording to 3A; Ra-values ≤ 0.8 µm (32 µ-inch)/welds Ra) ≤ 0.8 µm (32 µ-inch) | |||

Power supply UH | Supplied through bus | |||

Terminal voltage on transmitter | 10.5 ... 45 V DC | - | ||

Separate 24 V power supply necessary | - | No | ||

Bus voltage | ||||

| - | 9 ... 32 V | ||

| - | 9 ... 24 V | ||

Current consumption | ||||

| - | 12.5 mA | ||

| - | Yes | ||

| - | 15.5 mA | ||

Fault disconnection electronics (FDE) available | - | Yes | ||

Certificates and approvals | ||||

Classification according to PED 97/23/EC | For gases of fluid group 1 and liquids of fluid group 1; complies with requirements of article 3, paragraph 3 (sound engineering practice) | |||

Explosion protection | ||||

| PTB 99 ATEX 2122 | |||

| Ex II 1/2 G EEx ia/ib IIB/IIC T6 | |||

| -40 ... +85 °C (-40 ... +185 °F) temperature class T4; | |||

| To certified intrinsically-safe circuits with peak values: | FISCO supply unit: Linear barrier: | ||

| Li = 0.4 mH, Ci = 6 nF | Li = 7 μH, Ci = 1.1 nF | ||

| PTB 99 ATEX 1160 | |||

| Ex II 1/2 G EEx d IIC T4/T6 | |||

| -40 ... +85 °C (-40 ... +185 °F) temperature class T4; | |||

| To circuits with values: UH = 10.5 ... 45 V DC | To circuits with values: UH = 9 ... 32 V DC | ||

| PTB 01 ATEX 2055 | |||

| Ex II 1 D IP65 T 120 °C | |||

| -40 ... +85 °C (-40 ... +185 °F) | |||

| 120 °C (248 °F) | |||

| To certified intrinsically-safe circuits with peak values: | FISCO supply unit: Linear barrier: | ||

| Li = 0.4 mH, Ci = 6 nF | Li = 7 μH, Ci = 1.1 nF | ||

| PTB 01 ATEX 2055 | |||

| Ex II 2 D IP65 T 120 °C | |||

| To circuits with values: UH = 10.5 ... 45 V DC; Pmax = 1.2 W | To circuits with values: UH = 9 ... 32 V DC; Pmax = 1.2 W | ||

| TÜV 01 ATEX 1696 X | Planned | ||

| Ex II 3 G EEx nA L IIC T4/T5/T6 | - | ||

| Certificate of Compliance 3008490 | |||

| CL I, DIV 1, GP ABCD T4...T6; CL II, DIV 1, GP EFG; CL III; CL I, ZN 0/1 AEx ia IIC T4...T6; CL I, DIV 2, GP ABCD T4...T6; CL II, DIV 2, GP FG; CL III | |||

| Certificate of Compliance 1153651 | |||

| CL I, DIV 1, GP ABCD T4...T6; CL II, DIV 1, GP EFG; CL III; Ex ia IIC T4...T6; CL I, DIV 2, GP ABCD T4...T6; CL II, DIV 2, GP FG; CL III | |||

1) Conversion of temperature error per 28 °C. Valid for temperature range -3 ... +53 °C < (0.064 . r + 0.08) % / 28 °C (50 °F).

Hygiene version

In the case of SITRANS P DSIII with 7MF413x flush-mounted diaphragm, selected connections comply with the requirements of EHEDG.

HART communication | |

|---|---|

HART | 230 ... 1100 Ω |

Protocol | HART Version 5.x |

Software for computer | SIMATIC PDM |

PROFIBUS PA communication | |

|---|---|

Simultaneous communication with master class 2 (max.) | 4 |

The address can be set using | Configuration tool or local operation (standard setting address 126) |

Cyclic data usage | |

| 5 (one measured value) or |

| 0, 1, or 2 (register operating mode and reset function for metering) |

Internal preprocessing | |

Device profile | PROFIBUS PA Profile for Process Control Devices Version 3.0, Class B |

Function blocks | 2 |

| |

| Yes, linearly rising or falling characteristic |

| 0 & 100 s |

| Input /Output |

| parameterizable (last good value, substitute value, incorrect value) |

| Yes, one upper and lower warning limit and one alarm limit respectively |

| Can be reset, preset, optional direction of counting, simulation function of register output |

| parameterizable (summation with last good value, continuous summation, summation with incorrect value) |

| One upper and lower warning limit and one alarm limit respectively |

| 1 |

Transducer blocks | 2 |

| |

| Yes |

| Yes |

| Max. 30 nodes |

| Yes |

| Parameterizable |

| Constant value or over parameterizable ramp function |

FOUNDATION Fieldbus communication | |

|---|---|

Function blocks | 3 function blocks analog input, 1 function block PID |

| |

| Yes, linearly rising or falling characteristic |

| 0 & 100 s |

| Output/input (can be locked within the device with a bridge) |

| parameterizable (last good value, substitute value, incorrect value) |

| Yes, one upper and lower warning limit and one alarm limit respectively |

| Yes |

| Standard FOUNDATION Fieldbus function block |

| 1 resource block |

Transducer blocks | 1 transducer block Pressure with calibration, 1 transducer block LCD |

| |

| Yes |

| Yes |

| Constant value or over parameterizable ramp function |

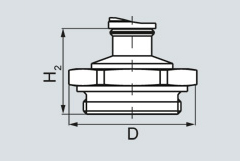

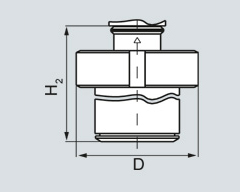

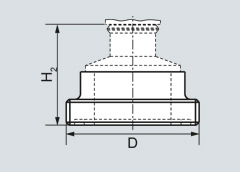

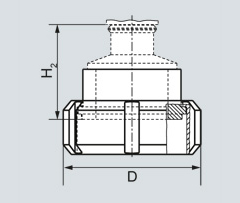

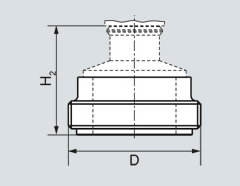

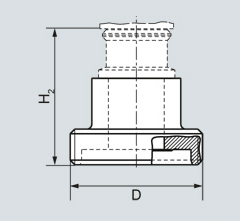

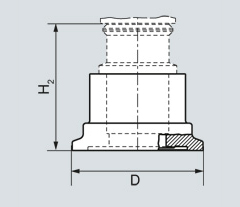

SITRANS P pressure transmitters, DS III series for gage pressure, with flush-mounted diaphragm, dimensions in mm (inch)

The diagram shows a SITRANS P DS III with an example of a flange. In this drawing the height is subdivided into H1 and H2.

H1 = Height of the SITRANS P300 up to a defined cross-section

H2 = Height of the flange up to this defined cross-section

Only the height H2 is indicated in the dimensions of the flanges.

Flange to EN

EN 1092-1 | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

25 | 40 | 115 mm (4.5") | Approx. 52 mm (2") | |

25 | 100 | 140 mm (5.5") | ||

40 | 40 | 150 mm (5.9") | ||

40 | 100 | 170 mm (6.7") | ||

50 | 16 | 165 mm (6.5") | ||

50 | 40 | 165 mm (6.5") | ||

80 | 16 | 200 mm (7.9") | ||

80 | 40 | 200 mm (7.9") | ||

Flanges to ASME

ASME B16.5 | ||||

|---|---|---|---|---|

|

| DN | Class | ∅D | H2 |

1“ | 150 | 110 mm (4.3") | Approx. 52 mm (2") | |

1“ | 300 | 125 mm (4.9") | ||

1½“ | 150 | 130 mm (5.1") | ||

1½“ | 300 | 155 mm (6.1") | ||

2“ | 150 | 150 mm (5.9") | ||

2“ | 300 | 165 mm (6.5") | ||

3“ | 150 | 190 mm (7.5") | ||

3“ | 300 | 210 mm (8.1") | ||

4“ | 150 | 230 mm (9.1") | ||

4“ | 300 | 255 mm (10.0") | ||

Connections to DIN

DIN 11851 (milk pipe union) | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 25 | 92 mm (3.6") | Approx. 52 mm (2") | |

80 | 25 | 127 mm (5.0") | ||

TriClamp to DIN 32676 | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 16 | 64 mm (2.5") | Approx. 52 mm (2") | |

65 | 16 | 91 mm (3.6") | ||

Other connections

Varivent connection | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

40 ... 125 | 40 | 84 mm (3.3") | Approx. 52 mm (2") | |

Biocontrol connection | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 16 | 90 mm (3.5") | Approx. 52 mm (2") | |

65 | 16 | 120 mm (4.7") | ||

Sanitary process connection to DRD | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

65 | 40 | 105 mm (4.1”) | Approx. 52 mm (2") | |

Sanitary process screw connection to NEUMO Bio-Connect | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 16 | 82 mm (3.2") | Approx. 52 mm (2") | |

65 | 16 | 105 mm (4.1”) | ||

80 | 16 | 115 mm (4.5”) | ||

100 | 16 | 145 mm (5.7") | ||

2” | 16 | 82 mm (3.2") | ||

2½” | 16 | 105 mm (4.1”) | ||

3” | 16 | 105 mm (4.1”) | ||

4” | 16 | 145 mm (5.7") | ||

Sanitary process connection to NEUMO Bio-Connect flange connection | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 16 | 110 mm (4.3") | Approx. 52 mm (2") | |

65 | 16 | 140 mm (5.5”) | ||

80 | 16 | 150 mm (5.9”) | ||

100 | 16 | 175 mm (6.9") | ||

2” | 16 | 100 mm (3.9") | ||

2½” | 16 | 110 mm (4.3”) | ||

3” | 16 | 140 mm (5.5”) | ||

4” | 16 | 175 mm (6.9") | ||

Sanitary process connection to NEUMO Bio-Connect clamp connection | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 16 | 77.4 mm (3.0") | Approx. 52 mm (2") | |

65 | 10 | 90.9 mm (3.6") | ||

80 | 10 | 106 mm (4.2") | ||

100 | 10 | 119 mm (4.7") | ||

2” | 16 | 64 mm (2.5") | ||

2½” | 16 | 77.4 mm (3.0”) | ||

3” | 10 | 90.9 mm (3.6”) | ||

4” | 10 | 779 mm (4.7") | ||

Sanitary process connection to NEUMO Bio-Connect S flange connection | ||||

|---|---|---|---|---|

|

| DN | PN | ∅D | H2 |

50 | 16 | 125 mm (4.9") | Approx. 52 mm (2") | |

65 | 10 | 145 mm (5.7") | ||

80 | 10 | 155 mm (6.1") | ||

100 | 10 | 180 mm (7.1") | ||

2” | 16 | 125 mm (4.9") | ||

2½” | 10 | 135 mm (5.3”) | ||

3” | 10 | 145 mm (5.7") | ||

4” | 10 | 180 mm (7.1") | ||

Threaded connection G¾", G1" and G2" acc. to DIN 3852 | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

¾“ | 63 | 37 mm (1.5") | approx. 45 mm (1.8") | |

1“ | 63 | 48 mm (1.9") | approx. 47 mm (1.9") | |

2“ | 63 | 78 mm (3.1") | Approx. 52 mm (2") | |

Tank connection TG 52/50 and TG52/150 | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

25 | 40 | 63 mm (2.5") | approx. 63 mm (2.5") | |

25 | 40 | 63 mm (2.5") | approx. 170 mm (6.7") | |

SMS socket with union nut | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

2“ | 25 | 84 mm (3.3") | Approx. 52 mm (2.1") | |

2½“ | 25 | 100 mm (3.9") | ||

3“ | 25 | 114 mm (4.5") | ||

SMS threaded socket | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

2“ | 25 | 70 x 1/6 mm | Approx. 52 mm (2.1") | |

2½“ | 25 | 85 x 1/6 mm | ||

3“ | 25 | 98 x 1/6 mm | ||

IDF socket with union nut | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

2“ | 25 | 77 mm (3") | Approx. 52 mm (2.1") | |

2½“ | 25 | 91 mm (3.6") | ||

3“ | 25 | 106 mm (4.2") | ||

IDF threaded socket | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

2“ | 25 | 64 mm (2.5") | Approx. 52 mm (2.1") | |

2½“ | 25 | 77.5 mm (3.1") | ||

3“ | 25 | 91 mm (3.6") | ||

Aseptic threaded socket to DIN 11864-1 Form A | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

50 | 25 | 94 | Approx. 52 mm (2.1") | |

65 | 25 | 113 | ||

80 | 25 | 133 | ||

100 | 25 | 159 | ||

Aseptic flange with notch to DIN 11864-2 Form A | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

50 | 16 | 78 x 1/6" | Approx. 52 mm (2.1") | |

65 | 16 | 95 x 1/6" | ||

80 | 16 | 110 x 1/4" | ||

100 | 16 | 130 x 1/4" | ||

Aseptic flange with groove to DIN 11864-2 Form A | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

50 | 16 | 94 | Approx. 52 mm (2.1") | |

65 | 16 | 113 | ||

80 | 16 | 133 | ||

100 | 16 | 159 | ||

Aseptic clamp with groove to DIN 11864-3 Form A | ||||

|---|---|---|---|---|

| DN | PN | ∅D | H2 |

50 | 25 | 77,5 | Approx. 52 mm (2.1") | |

65 | 25 | 91 | ||

80 | 16 | 106 | ||

100 | 16 | 130 | ||

| Код | Заказной номер | Описание | Заказать |

|---|---|---|---|

| 117949 | 7MF4133-.....-.... | преобразователь давления sitrans p для избыточного давления серии ds iii hart, конструкция с плоской мембраной | Заказать |

| 117950 | 7MF4134-.....-.... | преобразователь давления sitrans p для избыточного давления серии ds iii pa, конструкция с плоской мембраной | Заказать |

| 71447 | 7MF4135-.....-.... | преобразователь sitrans p для избыточного давления, конструкция с плоской мембраной серии ds iii ff (foundation fieldbus) | Заказать |